Atomic I/O letters column #118

Originally published 2010, in Atomic: Maximum Power ComputingReprinted here June 20, 2011 Last modified 16-Jan-2015.

Battery building

I bought a used laptop. The battery was dead. I cut it apart and found out what sort of lithium ion cells it used and bought six more of them on eBay. I stuck those cells together with wire and sticky tape and Blu-Tacked the wires into the gutted battery shell and verified that the laptop would charge them and run from them. Yay me.

So now I need to solder the cells together with little bits of wire so I can stuff them back into the battery casing.

How the hell do you do that? The solder doesn't stick! Do I need a special soldering iron? Can you only connect these cells with the little factory welded tab things?

Alana

Of all the things I've taken pictures of for this column, this is definitely

one of them.

Answer:

Any electronics soldering iron (so, not a huge plumbing iron; a 25-watt

eBay cheapie will work fine), with a chisel tip on it, will work for soldering battery

cells.

(The standard point tip won't work, though, and that's all you'll get with an eBay cheapie iron. It's therefore probably less hassle to get a basic iron plus a chisel tip to suit from a local dealer.)

You may have trouble getting cells with folded wire between them to fit where cells with thin spot-welded tabs were before, but the soldering, at least, is not hard.

The secret, besides not using a small pointy tip on your iron, is to scratch up the ends of the cells. Sandpaper, a Dremel grinding bit, the corner of a file; anything that roughens the surface. Now you should be able to easily "tin" the end of the cell almost as soon as you touch iron and solder to it, then press the similarly-tinned wire onto the end of the cell with the iron, remove the iron, and hold the wire still until the solder solidifies and it's stuck. Done.

If the solder doesn't flow over the surface pretty much instantly, you're doing it wrong. It's easy to overheat and damage the cell this way. Practice on cheap non-rechargeable batteries - old flat ones, if you're especially nervous - until you get the technique down.

Cool, but furry

I felt like a suuuuper genius when I upgraded my computer's cooling for summer by removing the faceplates for all of the unused 5.25-inch bays. That made room for a quiet but powerful 140mm fan in the front of the bays. Every temperature reading instantly dropped by 15 degrees. No more mid-game CPU speed throttling!

But now, of course, there aren't just dust bunnies inside my PC. More, dust wombats. Dust sculptures. Dust tribble orgies.

OK, I'm an idiot for not putting a dust catcher on the front of the new fan hole. But now I can't find the right sort of filter foam to put there. The hole's too big for 80 or 92 or even 120mm fan filters, even if I had some way of mounting one there. What should I do?

Joseph

Answer:

Try flyscreen.

Fine flyscreen won't catch really tiny dust particles nearly as well as the scratchy open-cell foam of normal dust filters, but you'll find it'll catch quite a lot of stuff - especially pet hair, if that's an issue.

Failing that, there are free-flowing filter materials that come in large sheets, for use in heating, ventilation and air-conditioning ("HVAC") applications. They're quite cheap (especially if you can cut one sheet into 50 disposable computer-filters...), but you may need to call around a bit to find a supplier. Obviously, your local air-con installer may have some leads for you.

A strapping lad

OK, so if I want to work on my computer without buying a ticket in the Wreck Your Hardware Lottery, I need an anti-static wrist strap. Got it.

So I'm looking on eBay for them, and they cost about nothing, so that's great... but there are two kinds.

One kind has a curly cord going from the Velcro strap to an alligator clip and/or banana plug. But the other kind is "wireless" or "cordless", with no cord at all, just a little metal stud or screw sticking out.

That certainly sounds more convenient. How does it work? Corona discharge?

Marc

Answer:

Cordless anti-static wrist straps do not actually work

at all.

Like the mobile-phone antenna-booster sticker, the performance-enhancing magic sports bracelet, the ultrasonic mosquito repeller and this thing, they are pure placebo.

Unlike most such devices, though, cordless anti-static straps can do harm, by making you think you're protected from static-zapping components when you're not. Much better to use the standard half-assed no-strap anti-static precautions (leave computer plugged into the wall so its chassis is earthed, and touch the chassis periodically while working) than to use a placebo.

Proper wrist straps aren't much less convenient, by the way. Even in the case of the $1 eBay specials, the cord is usually attached to the strap with a metal press-stud, so you don't have to remove and replace the actual strap every time you move away from the computer.

To enjoy the full cordless-strap experience, just forget to reconnect the cord when you come back!

(Fortunately, real anti-static wrist straps cost about the same nothing as the cordless, useless, ones.)

Single point of power

Can I run a number of 12V devices from a single AC adapter?

Presently I have 3 devices each with their own AC adapter putting out 12V between 0.5A - 2A. If I found an appropriate AC adapter (maybe a 3A or 4A adapter) could I just split the output from the one adapter to all of the various devices?

And will running a device using a correct voltage adapter but with a higher than originally specified current cause any problems?

(If you're wondering, the devices are modem, 8 port gigabit switch, and a dual band wireless AP - and yes I know that you can get a single integrated device that almost does all of the above.)

James

Answer:

Yes, you can do this. It's conceivable that one of the devices will do something like

emit noise down its power lead that one of the other devices won't like, but it's very

unlikely.

Herewith, the ways in which you can get this wrong:

1. Using an unregulated power supply, that gives more volts when it's not fully loaded. Not likely these days, since practically every off-the-shelf AC adapter is a lightweight switchmode regulated unit, but perfectly possible if you fish some dusty old power supply out of a bits box. If in doubt, stick a multimeter across the "12V" output with the power supply unloaded. A small amount of variation - say, 11V to 13V - is unlikely to be a problem, but a lightly-loaded unregulated "12V" supply can deliver more than 16V.

(If the multimeter shows a strange wavering near-zero voltage in DC-volts mode, switch to AC mode and see if you get a reading. There is such a thing as an AC-to-AC plugpack; modems often used them. 12V halogen downlight transformers are all AC units as well, in case you care.)

If the voltage is regulated, it doesn't matter how excessive the current capacity of a power supply is, for analogous reasons to those that protect you from the entire contents of your municipal water tower blasting into your kitchen when you turn on the tap. You can take the minuscule battery out of a 12V car-alarm remote and power the remote from the car's own 12V battery, even though that battery can deliver hundreds of amps to start the car.

2. Getting the polarity wrong. Most gear these days uses barrel-plug connectors with inside-contact positive, outside-contact negative, but don't make assumptions. Or, of course, mix up the wires when you're making your new multi-header power lead. (You can buy multi-head barrel-plug splitters off the shelf, by the way; they're used to run a bunch of separate guitar effects pedals from one power supply. If the gear you're powering doesn't all have the same size of barrel socket as an effects pedal, though, you'll be out of luck with one of these.)

3. Overloading the power supply. As you say, you should add the power ratings of the existing devices to get the amperage spec for the new power supply. Then I'd add about another amp for comfort.

Read the power specs off the labels on the devices, if they have them, rather than reading the labels on their plugpacks. The peak specified draw of a device may be rather less than the maximum rating of its plugpack.

You're probably still going to need more power than any standard regulated plugpack can deliver, so I'm tempted to suggest you use a dirt cheap "universal laptop PSU" off eBay for this job, but quality-control on those is pretty awful. I wouldn't be even slightly surprised if a cheap universal laptop PSU died after a week and took all of the things it was powering with it.

Proper electronics stores (the kind that aren't just mobile phone shops with a name that used to belong to a proper electronics store...) will have a range of power supplies, and you should be able to get a solid 12V unit to suit your purposes for around the $50 mark - see this one from an Australian store, for instance. Proper industrial PSUs don't cost much more.

You could also use just the 12V output of an old PC PSU (the yellow wire on the drive-power plugs). Loading just one rail of a PSU used to be a bad idea, but even cheap modern PSUs are generally fine with that, and they'll barely notice a few-amp load anyway.

Clan laser projectors, or Inner Sphere?

Now that red, green and blue laser pointers exist, there must be full colour laser video projectors too, right?

I understand that laser projectors don't need focussing, because the beams don't spread out. They're like an old CRT monitor, just scanning a coloured dot over whatever you point them at.

So why doesn't anybody sell one?

Are they only good for old-fashioned vector graphics? Can they only draw narrow bright scanlines with dark gaps in between? Do they blind you if you look down the barrel? What's the problem?

O.

Answer:

Actually, you can buy a

laser video projector

today. It'll just be one of those pocket-sized low-brightness "micro-projectors", whose

reason for existence is unclear.

Most of the world's laser projectors are indeed vector-graphics units, because they're one- or two-colour disco-lights. But full-colour raster-graphics laser video projectors do exist.

Because you can tweak the "collimation" of a laser beam to give it as much divergence as you like, it's easy to make a laser video projector's output no more scan-line-y than that of an old-style heavyweight CRT projector. (Some laser video projectors scan a dot, CRT-style; others spread the beam into a whole line and modulate that with micromirrors, like a DLP projector.)

Industrial-scale laser projectors can definitely be a serious eye hazard, but because 1000 separated one-millisecond exposures to laser light are much less dangerous than a single one-second exposure (the fluid in your eye sinks the heat away from the retina, given a chance, as I explain interminably in my old laser review here), a domestic laser projector with the same image brightness as a conventional projector isn't any more dangerous.

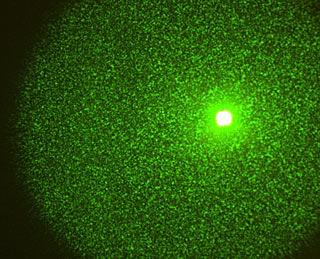

The problem, rather, is speckle patterns.

To save space on this page, I'll wait while you read the Wikipedia article about speckle patterns. Essentially, you'll see speckle whenever laser light - including light from the pocket-sized laser micro-projectors - bounces off something. And it's rather distracting. Never mind your DLP "rainbow effect" or LCD "screen door"; speckle won't go away even if you deliberately unfocus your eyes!

Domestic laser projectors remain a really cool idea, though, so there's a lot of work going into speckle-reduction. Multi-angle illumination, spinning diffusers, vibrating screens; the list goes on. Mitsubishi already make a couple of staggeringly expensive laser-rear-projection TVs that use these tricks.

So one day, you'll be able to alarm your suburb with Dead Space 3 projected onto low cloud.

I wouldn't hold my breath, though.